Rough In Ready Electrical

Roland alesi project manager colton electric rough in ready corporate office.

Rough in ready electrical. Wet bar lighting project. Methods that professional residential electricians follow in the us. You guys have been nothing short of amazing and i look forward to long business relationship with rough in ready. Pearson electrical service llc is focused on providing high quality service and customer satisfaction we will do everything we can to meet your expectations.

But the light switches outlets lights and other devices are not attached inspection of that aspect of the work occurs during the final inspection. Rough in ready illustrates the innovation that drives denier s efforts to continually improve productivity. Listed wiring system was initially developed by denier electric co inc. You can make copies for classroom instruction or individual use.

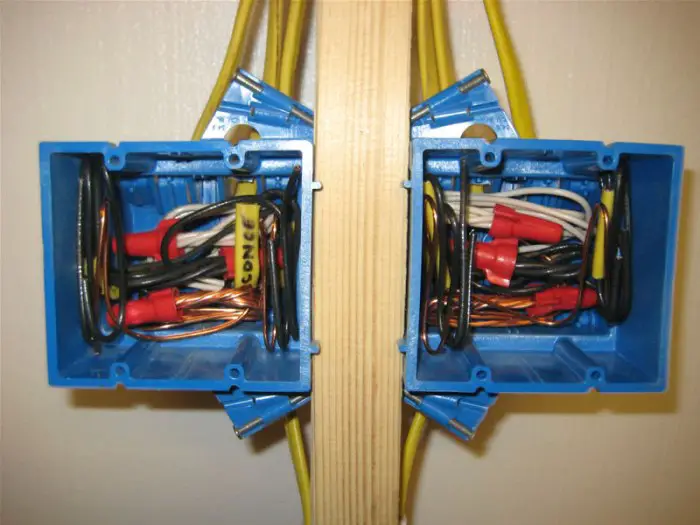

For use on our own construction projects. The rough in ready u. The first is called the rough in inspection this takes place when you have installed all of the electrical boxes cables conduit and wires to the point that you are ready for the walls to be closed up by surfaces. Any electrical project will profit from a rough in ready system but projects with many similar rooms provide the biggest benefit to the installer.

Back lit mirrors in master bath project. This article explains the rough in strategy of wiring a new house. We started our in house prefabrication department in 1979 and a design build electrical engineering division in 1980. Types of rough in.

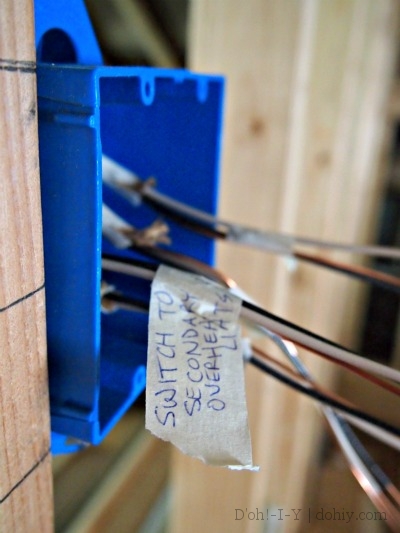

It is a great guide for beginner or commercial electricians or a training aid for electrical instructor s. We re ready to help you with your project. With electrical work a rough in means that all electrical cables have been pulled through studs and other framing members and are inserted into wall and ceiling boxes. Keep control of your project keep your crew working and garner the cost and time saving benefits of pre fab with basic ruff in assemblies.

New home construction rough in. Whether you run your own pre fab shop or simply want maximum project control eaton s basic ruff in prefabricated assemblies can provide a profitable solution that perfectly suits your operation. Our division started as an in house fabrication department then morphed into a center of development and manufacturing of new electrical support products for our own projects and now produces assemblies and products for national distribution. We hope you can find everything you need.