Electrical Resistance Probe Corrosion Monitoring

The increase in electrical resistance of a corroded element is measured in relation to that of a corresponding shielded reference element.

Electrical resistance probe corrosion monitoring. Ceion and electrical resistance er monitoring. Wire and tube loop elements are teflon or glass sealed. This technique operates by measuring the change in electrical resistance of a metallic element immersed in a product media relative to a. The most common type of corrosion probe is the linear polarization resistance probe lpr which is primarily used by the water industry and for high moisture environments.

Wire and tube loop elements are teflon or glass sealed. The electrical resistance er technique is an on line method of monitoring the rate of corrosion and the extent of total metal loss for any metallic equipment or structure. The operating principle is based on the change in resistance of the probe element as it is exposed to corrosive conditions. This method may be used in virtually any environment except liquid metals or some conductive molten salts.

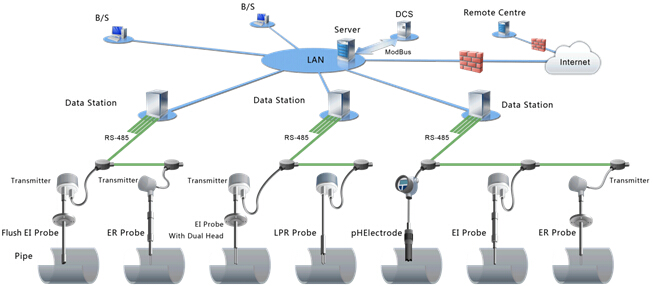

The operating principle is based on the change in resistance of the probe element as it is exposed to corrosive conditions. These probes provide very precise readings and are suitable for monitoring fluctuations such as corrosion inhibitor effects on a routine basis. The electrical resistance technique is one of the most widely used methods for measuring material loss occurring in the interior of plant and pipelines. Ceion and electrical resistance er monitoring.

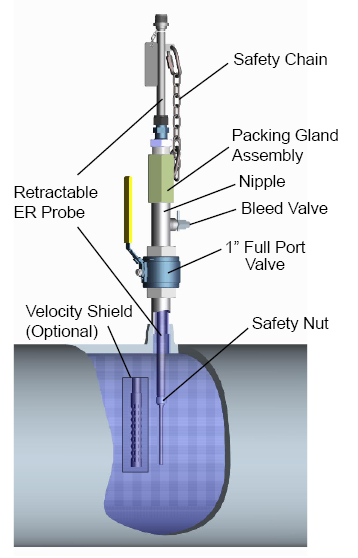

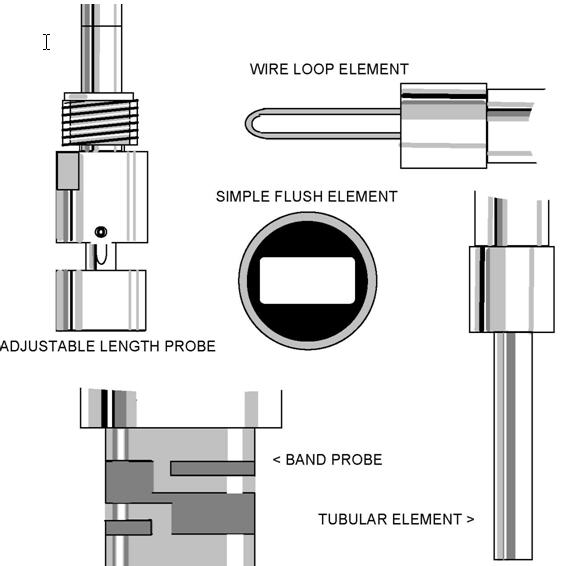

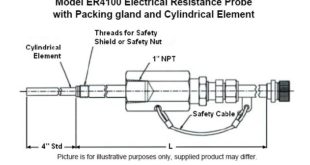

The uncorroded reference element also serves to compensate for the effects of temperature changes on resistance. Like coupons electrical resistance probes provide a basic measurement of metal loss but unlike coupons the value of metal loss can be measured at any time as frequently as required while the probe is in situ and permanently exposed to the process stream. The er technique measures the effects of both the electrochemical and the mechanical components of corrosion such as erosion or cavitation. Metal samples manufactures electrical resistance probes for corrosion monitoring in wire loop tube loop flush mount and cylindrical element configurations.

The cormon ceion and er systems are based on the fundamental concept that the action of corrosion on an exposed metal element will reduce the cross sectional area of the element thereby increasing its electrical resistance. Metal samples manufactures electrical resistance probes for corrosion monitoring in wire loop tube loop flush mount and cylindrical element configurations. Er instruments directly measure the metal loss on er probes. Er corrosion probes have been widely applied in oil and gas industry.